Case

Carmo integrates automated CO2 calculator in the ERP-system

Carmo has implemented an automated CO2 calculator that provides precise and continuously updated data on the climate footprint of their products.

Carmo has implemented an automated CO2 calculator that provides precise and continuously updated data on the climate footprint of their products.

Carmo is a leading Danish manufacturer of plastic components, primarily for the medical industry. They sought to enhance their climate strategy by automating the calculation of their products' CO2 footprint.

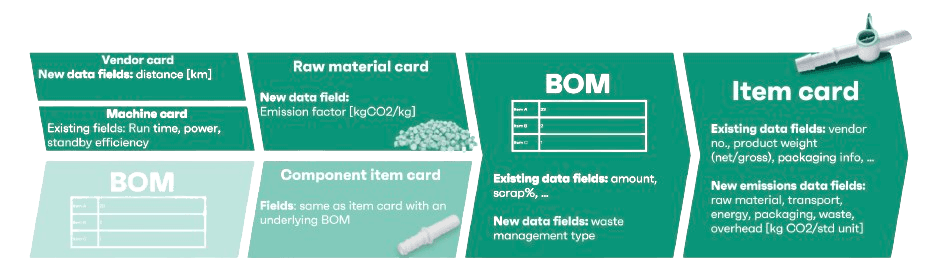

In collaboration with Viegand Maagøe and ERP specialists from Vektus, an automated CO2 calculator was developed, integrating lifecycle assessment (LCA) directly into Carmo's ERP system, Business Central (BC). This solution enables a comprehensive CO2 calculation for all plastic components, from raw materials to factory output, based on both production and logistical parameters.

This allows Carmo to continuously monitor and reduce their environmental impact while offering their customers transparent data for use in carbon accounting.

To meet Carmo's needs, Viegand Maagøe developed an advanced CO2 calculator based on ISO 14040/44 standards. The calculator was integrated into Carmo's ERP system, collecting data from multiple sources such as energy consumption, material usage, waste management, and transportation. The system uses emission factors from ecoinvent v3.10 and the IPCC AR6 method to measure CO2 emissions from plastic production.

The automated calculator considers:

• Emissions from raw materials, including waste.

• Energy consumption for injection molding machines, electric forklifts, and robots.

• Waste management of production scrap and defective products.

• Transportation of materials from suppliers to Carmo.

• Overhead emissions from administration and building operations.

This integrated solution also allows for future updates, such as supplier-specific data and annual updates of energy factors, ensuring ongoing accuracy and improvements.